4130 Heat Treat Chart

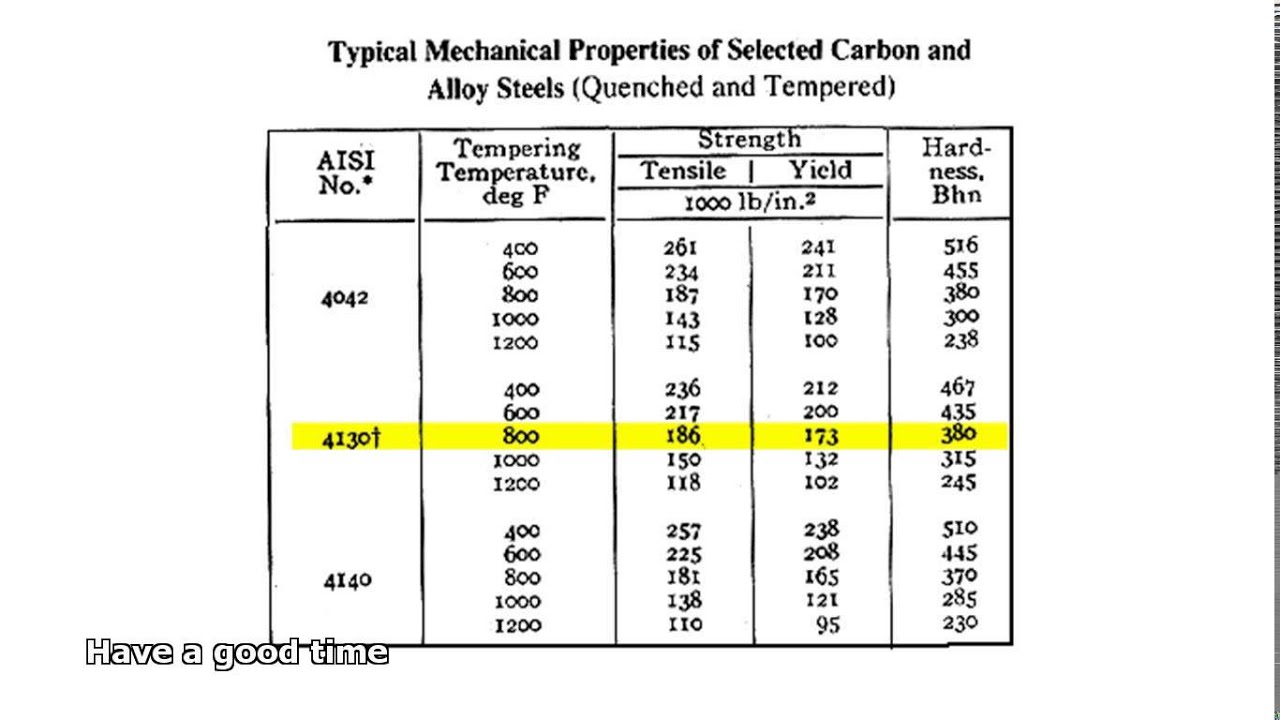

4130 Heat Treat Chart - It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). It has low carbon content, and can be welded easily. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off road, hydraulic tools, and. The datasheet below provides further detail. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off road, hydraulic tools, and. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. It has low carbon content, and can be welded easily. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. The datasheet below provides further detail. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. It has low carbon content, and can be welded easily. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). It has a density of 7.85. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It has low carbon content, and can be welded easily. It typically contains 0.8% to. It has low carbon content, and can be welded easily. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars,. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It has low carbon content, and can be welded easily. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. The datasheet below provides further. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off road, hydraulic tools, and. It has low carbon content, and can be welded easily. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. The datasheet below provides further detail. It has a. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off. It has low carbon content, and can be welded easily. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It typically contains 0.8% to. The datasheet below provides further detail. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. Aisi 4130 alloy steel contains chromium and molybdenum. The datasheet below provides further detail. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. It has low carbon content, and can be welded easily. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems. It typically contains 0.8% to 1.1% chromium and 0.15% to 0.25% molybdenum,. 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off road, hydraulic tools, and. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). The datasheet below provides further detail. It. It has a density of 7.85 g/cm 3 (0.284 lb/in 3). 4130 (e4130) steel alloy is used primarily in the construction of commercial and military aircraft and ground support systems as well as automotive, race cars, off road, hydraulic tools, and. Aisi 4130 alloy steel contains chromium and molybdenum as strengthening agents. It has a density of 7.85 g/cm3 (0.284 lb/in3) and benefits from heat. The datasheet below provides further detail. Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability.Heattreated 4130 ability to withstand high torque with large angular deflection Metal and

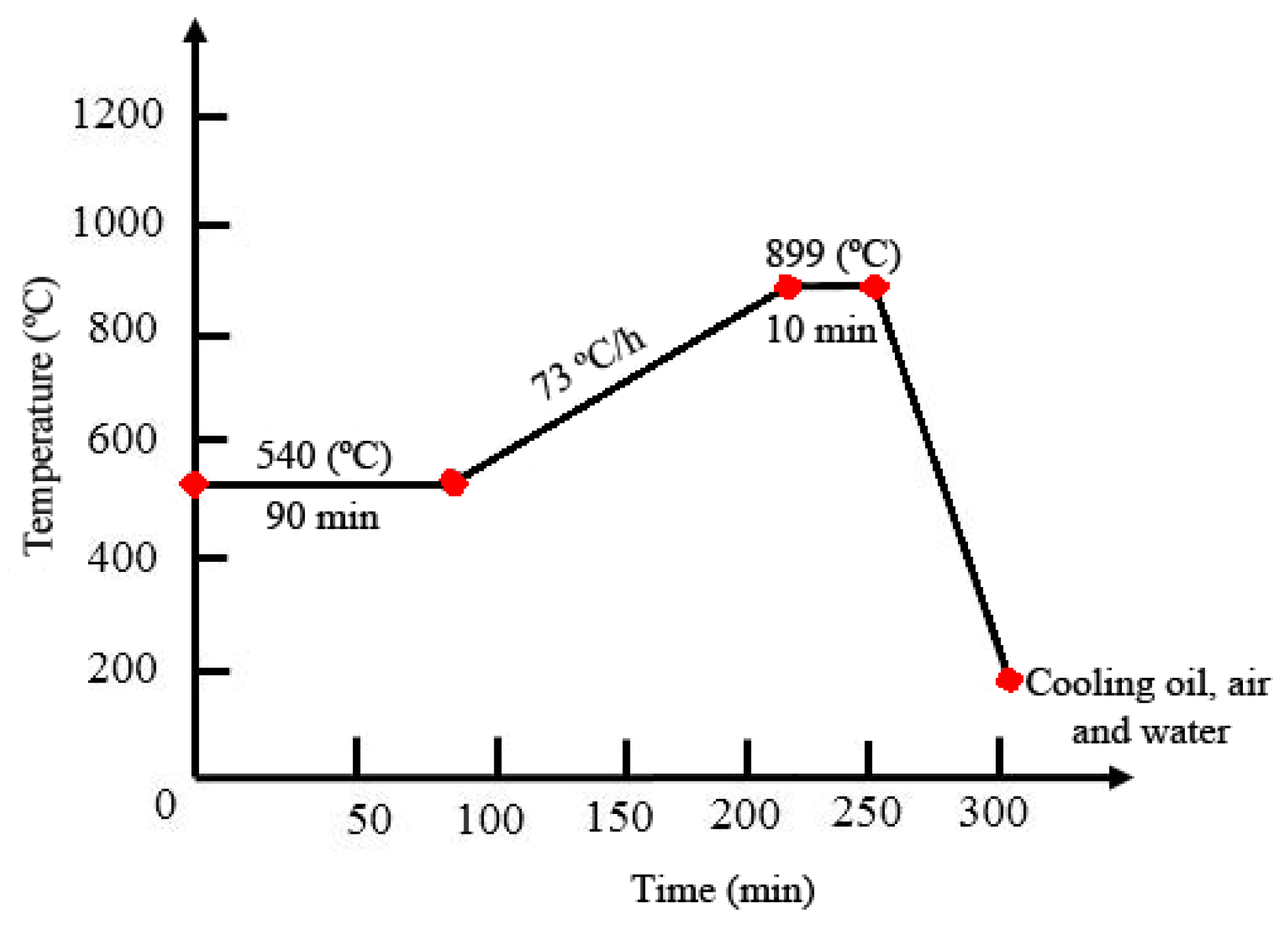

SciELO Brasil A Comparative Study of Abbreviated Heat Treatments for SAE 4130 Steel After

Heat Treat 4130 Tubing

4130 Heat Treat Chart A Visual Reference of Charts Chart Master

Effects of Fillerwire Composition along with Different Pre and PostHeat Treatment on

4130 steel YouTube

Spec 4140 & 4130 Heat Treating Annealing (Metallurgy)

4130 Tempering Chart A Visual Reference of Charts Chart Master

Materials Free FullText Experimental and Numerical Study of AISI 4130 Steel Surface

Heat Treatment Reference Chart for Material Grades 4130, 8630, 4140, 4340, and 4145 Indicating

It Typically Contains 0.8% To 1.1% Chromium And 0.15% To 0.25% Molybdenum,.

It Has Low Carbon Content, And Can Be Welded Easily.

Related Post: